Welding Applications

and Procedures

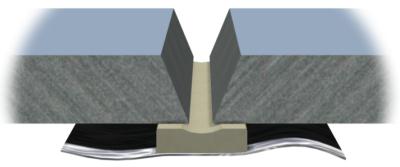

In the past, full penetration welding involved costly backgouging, grinding, and rewelding. With Cerbaco Ltd. non-metallic weld backings, you can achieve X-ray quality, full penetration welds from one side and in a single pass. The result is a finished high-quality weld and savings of labor, materials, and time.

Cerbaco weld backings are manufactured in many different configurations and in formulas for the diverse conditions encountered when welding anything from light gauge sheet metal to heavy metal fabrication.

Cerbaco weld backings can be used to compensate for poor fit-ups, and is a valuable tool when welding conditions are not ideal or where the back side of a weld joint is inaccessible.

Cerbaco weld backings are non-metallic, non-hygroscopic, neutral, and unlike metal backing bars, do not become part of the finished weld. When properly positioned and attached to the back side of a weld joint, your welds can be free of defects, eliminating rework and cleanup associated with poor root welds.

One-sided, one-pass, and one-sided multi-pass welds are possible with Cerbaco weld backings. Our backings support molten weld metal over a wide range of welding heats, resulting in uniform back beads of finished quality.

Procedure

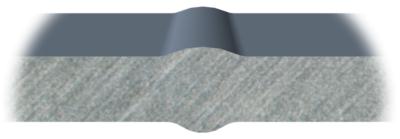

Step 1. Start With an Open Root:

Backing will vary depending on root opening, joint design, and welding process.

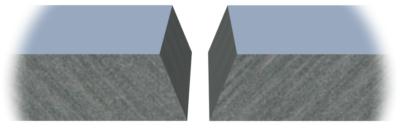

Step 2. Apply Backing:

In most applications, the backing is applied using our adhesive foil on which the backing is assembled. The area to which the backing will be attached should be free of loose rust, dirt, and oil.

Step 3. Weld:

Establish your arc and weld a root pass.